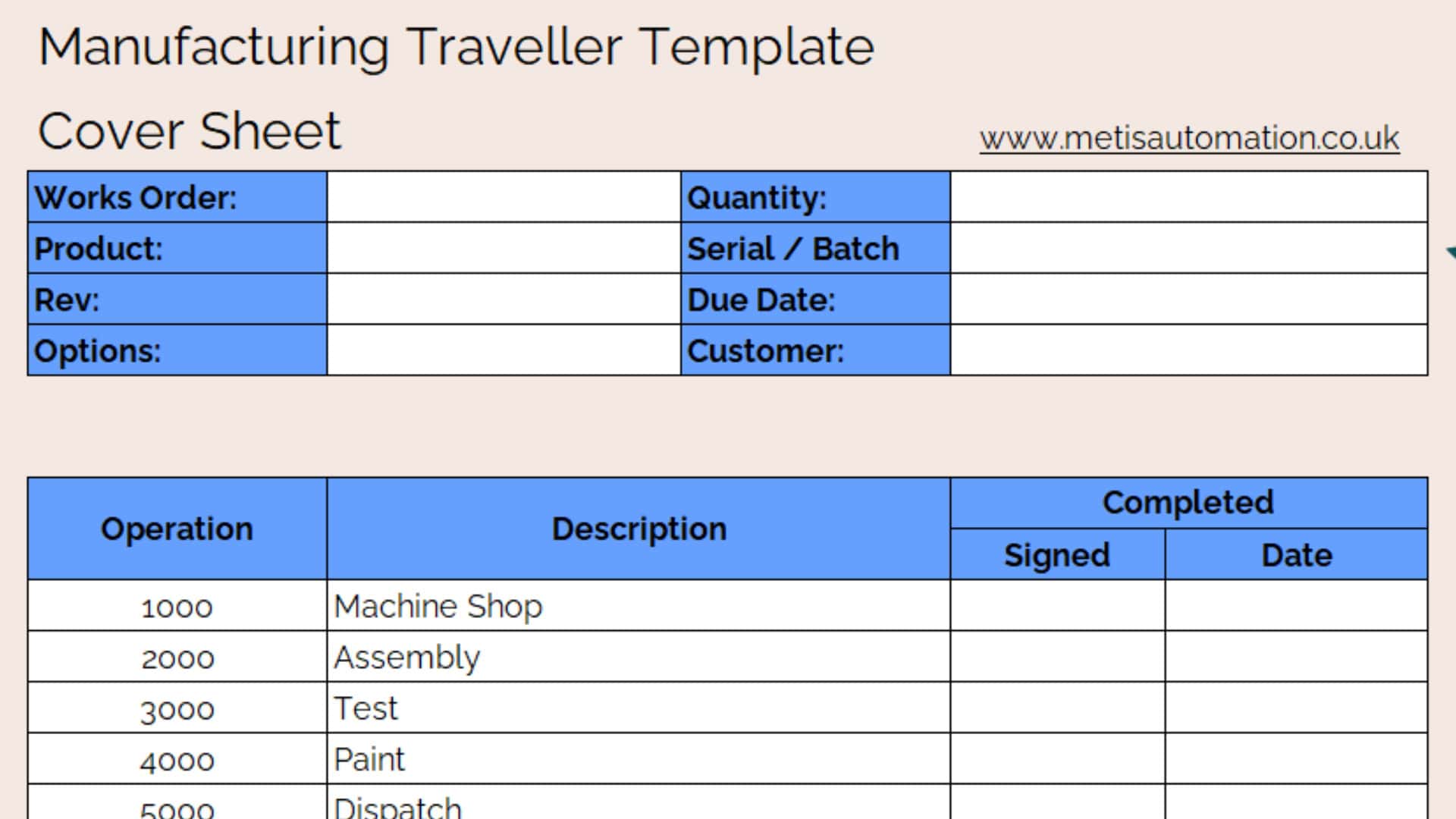

Defining Manufacturing Traveler Templates

A manufacturing traveler template is a standardized document used to track and manage the flow of materials, instructions, and information throughout a production process. It acts as a dynamic guide, providing crucial details at each stage of production, from raw materials to finished goods. These templates are essential for ensuring consistency, efficiency, and quality control within a manufacturing environment.

Manufacturing traveler templates are vital tools for streamlining production processes. They eliminate the need for searching through numerous documents and provide a clear, concise record of all necessary steps and information for each product or batch. This centralized system enhances communication between different departments and personnel, ensuring everyone is on the same page regarding the production requirements.

Manufacturing Traveler Template Components

Traveler templates typically contain a range of crucial information. Key components include detailed work instructions, material lists, quality control checks, and location tracking data. This detailed information allows for smooth transitions between production stages, facilitating a more organized and efficient manufacturing process. Each component plays a critical role in the overall success of the manufacturing operation.

Types of Manufacturing Traveler Templates

Different types of traveler templates cater to specific needs and manufacturing processes. The choice of template type depends on the complexity of the operation and the industry in which the manufacturing occurs. Some common types include work order travelers, material movement travelers, and inspection travelers.

Work Order Traveler

A work order traveler details the specific steps and procedures for completing a particular task or manufacturing order. It includes detailed instructions, material lists, and quality control standards for the operation. This ensures consistency in the manufacturing process, reducing errors and ensuring adherence to specifications.

Material Movement Traveler

This type of template tracks the movement of materials within the manufacturing facility. It includes information on the origin, destination, and quantity of materials being transferred. This information is critical for warehousing, logistics, and supply chain management. Accurate tracking of materials helps to optimize inventory management and minimize material waste.

Inspection Traveler

This traveler documents the inspection process for products or components. It includes details on the specific quality checks to be performed and the standards that must be met. This traveler ensures quality control at each stage of production. Detailed inspection records allow for quick identification of any defects and facilitate corrective actions.

Comparison of Traveler Template Types

| Template Type | Key Features | Applications | Example Use Cases |

|---|---|---|---|

| Work Order Traveler | Detailed work s, material lists, and quality control checks | Manufacturing processes requiring specific steps | Assembling a product, machining parts |

| Material Movement Traveler | Location tracking and material movement information | Warehousing, logistics, and supply chain management | Moving materials from storage to production |

| Inspection Traveler | Quality control checks, standards, and documentation | Quality assurance and control | Inspecting finished products, checking components |

Benefits of Using Templates

Manufacturing traveler templates are more than just pretty documents; they’re powerful tools that can revolutionize your production process. By standardizing workflows and communication, these templates can significantly boost efficiency, reduce errors, and ultimately improve the bottom line. Imagine a factory floor where everyone knows exactly what to do, when, and how. That’s the potential of a well-implemented manufacturing traveler template system.

Implementing a structured approach to manufacturing travelers can lead to substantial improvements in various aspects of production. Templates provide a clear and concise framework for documenting and tracking tasks, materials, and schedules. This clarity is invaluable for streamlining communication between different departments and for ensuring that everyone is on the same page.

Enhanced Efficiency and Productivity

Manufacturing traveler templates streamline the production process by providing a standardized framework for each job. This reduces the time spent on figuring out tasks and procedures, allowing employees to focus on executing the work. When every step is clearly defined and documented, workers can move seamlessly from one task to the next, minimizing delays and maximizing output. This increased efficiency translates directly to higher productivity levels.

Reduced Errors and Improved Quality Control

Standardized procedures are the cornerstone of effective quality control. Templates ensure that every job is performed consistently, according to established best practices. This reduces the likelihood of errors, which, in turn, leads to improved product quality. By clearly defining the steps involved in each operation, templates help prevent inconsistencies and variations in the manufacturing process, thereby lowering the rate of defects. Accurate documentation also allows for easier identification of problem areas and opportunities for improvement.

Streamlined Communication Between Departments

Manufacturing traveler templates act as a central repository for information, facilitating seamless communication across different departments. When every aspect of a job is documented in a standardized format, there’s less chance of miscommunication or misunderstandings. This improved communication fosters collaboration and allows different departments to work together more effectively, ultimately leading to a smoother production flow. For instance, if a quality control department has questions about a particular stage of production, the traveler template provides readily accessible information, allowing them to respond swiftly and effectively.

Quantifiable Benefits of Using Templates

| Benefit | Explanation | Quantifiable Impact (Example) |

|---|---|---|

| Reduced Errors | Standardized processes minimize mistakes, leading to fewer defects. | Decrease in defects by 15% |

| Improved Communication | Clear instructions and standardized documentation enhance collaboration, resulting in more accurate and efficient communication. | Increased on-time deliveries by 10% |

| Reduced Lead Times | Streamlined workflows reduce the time required for each step in the manufacturing process. | Reduction in lead time by 8% |

| Increased Productivity | Standardized processes and clear communication reduce downtime and improve worker efficiency. | 10% increase in overall output |

Best Practices for Template Design

Crafting effective manufacturing traveler templates is crucial for streamlined operations and accurate record-keeping. A well-designed template ensures data integrity, facilitates communication, and reduces errors, leading to significant improvements in efficiency. This section delves into the key factors for designing robust and user-friendly manufacturing traveler templates.

A meticulously designed template serves as a central repository of crucial information, ensuring everyone involved understands the process steps, materials, and timelines. This uniformity promotes consistency and reduces the potential for miscommunication. By incorporating best practices, manufacturers can leverage traveler templates to maximize their efficiency and minimize delays.

Key Factors in Template Design

Template design should prioritize clarity and ease of use. This includes using clear and concise language, standardized abbreviations, and consistent formatting. Ambiguity and inconsistencies can lead to confusion and errors. A well-defined structure ensures that all necessary information is captured and easily accessible. Visual elements such as color-coding and intuitive layouts enhance understanding and aid in data retrieval.

Importance of Clarity, Consistency, and Accuracy

Clear and unambiguous language within the template is paramount. Using standardized terminology and avoiding jargon ensures that all stakeholders understand the instructions. Maintaining consistent formatting throughout the template ensures uniformity and minimizes errors in data entry. Accuracy is critical; incorrect information can lead to costly delays and rework. Rigorous proofreading and validation procedures are essential to guarantee accuracy.

Ensuring Data Integrity and Security

Data integrity is vital to the reliability of manufacturing travelers. Implementing validation rules, such as data type checks and range restrictions, helps maintain the accuracy of entered data. Version control mechanisms are essential to track changes and maintain the integrity of the template. Security measures should be incorporated to protect sensitive information from unauthorized access. This includes password protection and access controls based on user roles.

Adaptability to Different Manufacturing Processes

A versatile template design should accommodate diverse manufacturing processes. This involves using modular sections that can be easily added, removed, or modified depending on the specific requirements of each process. Flexibility allows the template to be tailored to various production stages and types of products. This adaptability prevents unnecessary complexities and ensures optimal use for all situations.

Best Practices for User-Friendly and Visually Appealing Templates

Designing user-friendly and visually appealing templates is key to their adoption. A user-friendly template is easily understood and navigated by all users, regardless of their technical expertise. Color-coding different sections can help users quickly identify relevant information. Clear headings, subheadings, and visual cues aid in comprehension.

Example of a Well-Structured Template

| Section | Description | Formatting |

|---|---|---|

| Process Step | Specific step in the manufacturing process. | Bold, Left-Aligned, Dark Blue |

| Material Requirements | List of materials needed for the step. | Bulleted List, Italicized, Green |

| Time Estimate | Estimated time required for the step. | Right-Aligned, Bold, Orange |

| Quality Checkpoints | List of quality checks required. | Bulleted List, Red |

A well-structured template with clear formatting, intuitive layouts, and color-coding for different sections will significantly improve the user experience and reduce errors.

Template Implementation and Maintenance

Manufacturing traveler templates, when implemented effectively, streamline production processes and enhance overall efficiency. However, the success of these templates hinges on a robust implementation strategy, proper employee training, and ongoing maintenance to adapt to changing needs. This section will detail the critical steps involved in ensuring the long-term effectiveness of your traveler template system.

Implementation Strategies

A smooth implementation process minimizes disruption and maximizes adoption. Start by identifying key personnel involved in each stage of production. These individuals should be consulted throughout the process, ensuring buy-in and understanding of the new system. Pilot testing with a small group allows for adjustments and refinements before widespread rollout, minimizing potential issues. Communicate clearly the benefits of the templates, focusing on improved efficiency and reduced errors. This helps build enthusiasm and promotes quicker adoption.

Employee Training Procedures

Comprehensive training is crucial for successful template utilization. Develop a structured training program, covering template navigation, data entry procedures, and potential troubleshooting scenarios. Interactive workshops and hands-on practice sessions are essential. Providing readily available reference materials, such as a user manual or FAQs, ensures ongoing support and knowledge retention. Consider offering follow-up sessions to address individual questions and concerns.

Maintenance and Updates

Regular template maintenance is essential to maintain accuracy and relevance. Establish a schedule for periodic reviews, ensuring templates align with current processes and procedures. Implement a version control system to track changes and revert to previous versions if necessary. This proactive approach prevents confusion and ensures all team members use the most up-to-date information.

Tracking and Analysis

Tracking template usage data provides valuable insights for improvement. Analyze metrics such as completion time, errors, and areas where the system is struggling to provide clarity. Identify potential bottlenecks and inefficiencies in the process, allowing for corrective actions and optimized workflows. Regular reports and dashboards can provide real-time visibility into the system’s performance.

Step-by-Step Implementation Guide

- Assessment: Evaluate existing workflows, identify areas for improvement, and select appropriate template structure.

- Design: Develop detailed templates that clearly Artikel the steps in each manufacturing process.

- Pilot Testing: Implement the template with a small group to identify and resolve any issues.

- Training: Provide comprehensive training to all relevant employees on template use, data entry, and troubleshooting.

- Rollout: Gradually introduce the templates to the entire team, providing ongoing support and addressing any questions.

- Monitoring: Track template usage, identify areas for improvement, and make necessary adjustments.

- Maintenance: Regularly review and update templates to reflect process changes and ensure accuracy.

Example of Template Update and Version Control

Consider a template for assembling a specific component. Initial version 1.0 Artikels the steps for assembly. Later, a new step (e.g., adding a secondary component) is introduced. The template is updated to version 1.1, adding the new step with clear instructions. Version history ensures traceability and allows reverting to the previous version if needed. This version control process helps manage changes effectively.

A table illustrating this version control:

| Version | Date | Description of Changes |

|---|---|---|

| 1.0 | October 26, 2023 | Initial template for component assembly |

| 1.1 | November 15, 2023 | Added step for secondary component addition |

Examples of Templates in Action: Manufacturing Traveler Template

Manufacturing traveler templates aren’t just theoretical concepts; they’re powerful tools that streamline production processes across various industries. From automotive assembly lines to intricate electronics manufacturing, these templates offer a standardized approach to tracking and managing production tasks, leading to significant improvements in efficiency and profitability. This section will delve into real-world applications, showcasing how these templates contribute to specific processes and boost overall productivity.

Applying standardized templates ensures consistent communication and data management, which is crucial in a complex manufacturing environment. This leads to better control over production flow, minimizing delays and errors. Using pre-defined templates helps maintain a high level of accuracy and reduces the potential for human error.

Automotive Manufacturing

Traveler templates in the automotive industry are critical for managing the complex assembly process of vehicles. A typical automotive traveler template would detail the specific parts required for a particular model, their order of assembly, and the necessary quality checks at each stage. For example, a template for assembling the engine compartment might list the engine, transmission, wiring harness, and various components, outlining the sequence of installation and quality checks for each. These templates also integrate with inventory management systems, ensuring that parts are readily available at each workstation, thus minimizing downtime and improving overall production speed.

Electronics Manufacturing

In the electronics industry, traveler templates help manage the intricate assembly and testing procedures for complex products like smartphones or laptops. These templates specify the required components, assembly steps, and quality control checkpoints. Consider a template for assembling a smartphone motherboard. This would detail the specific components (microprocessor, memory chips, etc.), their precise placement on the board, and a detailed inspection checklist to ensure functionality and adherence to specifications. The detailed nature of these templates allows for effective tracking of production progress, leading to accurate estimations of completion times.

Format and Layout for Different Processes

Traveler templates can adopt various formats to suit different production stages and processes. For instance, a Kanban-style traveler might visually depict the workflow through various stages, highlighting potential bottlenecks and areas for improvement. Another format could be a more traditional table format, clearly listing components, their quantities, and the specific work instructions for each.

Templates Across Production Stages

Templates are used across all phases of manufacturing. In the order entry stage, a template could capture customer orders, details, and the corresponding production requirements. A template for material procurement would ensure accurate order quantities and timely delivery. The production stage utilizes templates to track the progress of each unit, identify any deviations from the planned sequence, and trigger corrective actions if necessary. Quality control templates would detail the specific inspection criteria for each part and assembly stage.

Visual Representations of Traveler Templates

Imagine a Kanban-board-style representation of a traveler template for assembling a computer. Each stage of assembly (e.g., installing the CPU, adding RAM, connecting the motherboard) would be represented by a column. A card representing each computer unit in progress would move from column to column as it progresses through the assembly process. The cards could also contain specific information, like the unit number, the required components, and the quality checks performed at each stage. Another visual representation might use a flowchart to detail the step-by-step assembly of a complex product like a printer, including the necessary components, locations, and inspection procedures.

Planning a trip to manufacture something in Bolivia? A crucial part of that is sorting out your travel insurance. You’ll need a solid manufacturing traveler template to keep track of your schedule, contacts, and essential documents, and that’s where a reliable service like bolivia travel insurance comes in handy. Making sure your trip is protected is key to a smooth manufacturing process, so get your traveler template ready!

Planning a quick manufacturing trip? A well-organized traveler template is key. It’s all about efficiency, and a great template can help you manage everything from booking flights and accommodation to organizing meetings and site visits, especially when you’re focusing on a half-day travel itinerary like those detailed on halfday travel. A solid template will keep you on track and ensure you make the most of your time, ultimately streamlining the whole manufacturing process.