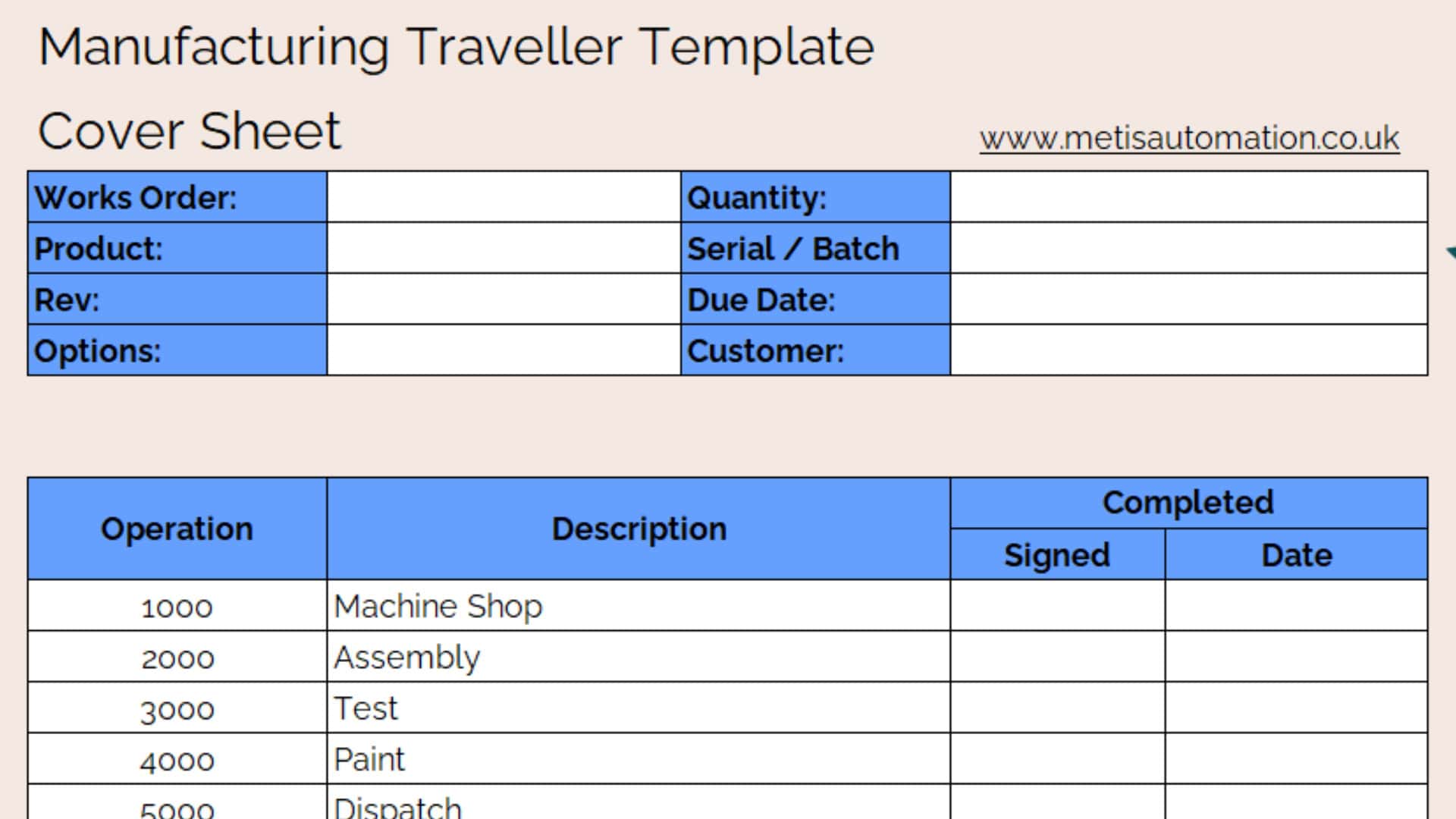

Introduction to Manufacturing Travelers: Manufacturing Traveler Example

Manufacturing travelers are essential tools for managing information and tracking processes within a manufacturing environment. They serve as a centralized repository for crucial data, facilitating communication and streamlining operations across different departments and stages of production. Their use enhances efficiency, reduces errors, and ultimately contributes to improved overall productivity.

Effective manufacturing travelers ensure smooth workflow and minimize delays. They facilitate the efficient exchange of information, empowering employees with the necessary data to make informed decisions and execute tasks accurately. The consistent use of travelers can contribute significantly to a more organized and productive manufacturing operation.

Defining Manufacturing Travelers

Manufacturing travelers are documents, either paper-based or digital, that contain specific information crucial to a particular manufacturing process or task. They serve as a standardized way to communicate critical details and instructions throughout the production line. These documents can range from simple checklists to complex blueprints, depending on the specific manufacturing operation.

Purpose and Benefits of Using Manufacturing Travelers

Manufacturing travelers offer a structured approach to tracking tasks and materials throughout the manufacturing process. This structure fosters transparency and accountability, minimizing errors and misunderstandings. The consistent use of travelers ensures that every stage of production adheres to established procedures and quality standards. This structured approach significantly reduces errors and promotes efficient workflow.

Common Use Cases

Manufacturing travelers are applicable across various industries. They are frequently used in assembly lines to track the progression of components through the manufacturing process. In quality control, they can record inspection results and highlight any deviations from standards. Travelers are also useful in logistics, documenting the movement of materials and ensuring timely delivery. Their versatility makes them adaptable to different manufacturing contexts.

Types of Manufacturing Travelers

Manufacturing travelers come in various formats, each offering distinct advantages. The choice of format depends on the specific needs and resources of the manufacturing operation. The most common types are paper-based and digital.

Traveler Type Comparison

| Traveler Type | Format | Primary Use | Advantages |

|---|---|---|---|

| Paper-based | Printed documents | Tracking, communication, documentation | Accessibility, offline use, lower initial cost |

| Digital | Software-based | Real-time data, reporting, collaboration, data analysis | Scalability, data sharing, improved accuracy, automation potential |

Key Components of a Manufacturing Traveler

A manufacturing traveler, a crucial document in the production process, acts as a dynamic guide, tracking the progress of a specific product or task. It’s a critical tool for maintaining visibility, accountability, and efficiency throughout the entire manufacturing journey. Understanding its key components is essential for streamlining operations and ensuring successful production.

Essential Elements, Manufacturing traveler example

The core components of a manufacturing traveler are meticulously designed to capture and communicate vital information. These elements, when used correctly, provide a comprehensive record of the journey of a product through the production line. Their structured format allows for easy tracking and analysis of various aspects of the production process.

Date

The date is a fundamental element, providing a timestamp for each stage of the production process. This allows for accurate tracking of the time taken at each step. By recording the date, manufacturers can monitor workflow efficiency and identify potential bottlenecks or delays. For example, if a particular operation is consistently taking longer than anticipated, the date stamp on the traveler will reveal this, allowing for corrective actions to be taken.

Employee ID

The employee ID is crucial for tracking accountability. Each step in the production process is assigned to a specific employee, who records their participation on the traveler. This feature allows manufacturers to easily identify who performed which tasks, aiding in quality control and performance evaluation. For instance, if a defect is found, the traveler’s employee ID provides a direct link to the individual responsible for that particular stage.

Table of Components and Functions

| Component | Description | Function |

|---|---|---|

| Date | The date and time the operation was completed. | Provides a timestamp for each stage, enabling efficient tracking of the production process. |

| Employee ID | The unique identification number assigned to each employee. | Tracks the employee responsible for each step, promoting accountability and enabling performance analysis. |

| Part Number | The unique identifier for the product being manufactured. | Facilitates the identification of the specific part being worked on and ensures the correct part is being processed. |

| Operation Number | A unique number assigned to each step in the production process. | Organizes the sequence of operations, allowing for clear tracking of the product’s progression through the manufacturing line. |

| Quantity | The number of units completed at each stage. | Tracks the quantity of units at each step, ensuring accuracy and preventing discrepancies. |

Format and Structure

The format of a manufacturing traveler should be standardized and easily understood. A clear layout, with distinct sections for each component (date, employee ID, part number, operation number, quantity, etc.), ensures data consistency and ease of analysis. A well-structured traveler allows for seamless integration with other manufacturing systems and processes. Using a pre-printed form or a digital template is highly recommended for consistency.

Examples in Manufacturing

In a car manufacturing plant, a manufacturing traveler might track the progress of a specific car chassis through the assembly line. The traveler would document the date and time each assembly operation was completed, the employee ID of the worker performing the task, the chassis number, the specific operation performed (e.g., attaching the engine), and the quantity of chassis completed. This detailed information is invaluable for quality control, inventory management, and identifying potential bottlenecks. Similarly, in a food processing plant, a manufacturing traveler could track the processing of a batch of cookies, recording the date, employee ID, cookie batch number, operation number (e.g., mixing, baking, cooling), and the quantity of cookies produced at each stage.

Data Collection Methods for Manufacturing Travelers

Manufacturing travelers are crucial for tracking production steps and materials. Accurate and efficient data collection is vital for maintaining production flow, ensuring quality control, and optimizing resource allocation. Effective data collection methods directly impact the overall efficiency and success of a manufacturing process.

Data collection methods for manufacturing travelers significantly influence the accuracy and speed of information flow within a production facility. Choosing the right method is critical, as it impacts the efficiency and reliability of the entire manufacturing process. Selecting a method involves careful consideration of the specific needs of the production line, such as the volume of data, the type of information being tracked, and the available resources.

Manual Data Entry

Manual data entry involves manually recording information from the manufacturing traveler. This method often relies on paper-based travelers and pen-and-paper entries. While simple in concept, it can be prone to human error and time-consuming.

- Advantages: Relatively inexpensive, easily implemented with existing systems, and suitable for small-scale operations.

- Disadvantages: High potential for errors, slow data input, difficult to maintain accuracy with high-volume production, and challenging to integrate with other systems.

Barcode Scanning

Barcode scanning uses optical readers to scan barcodes on materials and components. This method provides a quick and efficient way to collect data and reduce manual errors. The use of barcodes on parts and materials ensures traceability and accurate identification.

- Advantages: Improved data accuracy compared to manual entry, faster data collection, and easier integration with inventory management systems.

- Disadvantages: Requires barcoding of all items, potentially high initial investment in scanners and software, and the potential for scanning errors if barcodes are damaged or difficult to read.

Radio Frequency Identification (RFID)

RFID technology uses radio waves to transmit data from tags attached to items. This method provides real-time tracking of items and enables detailed tracking of location and status throughout the manufacturing process.

- Advantages: High accuracy, real-time data capture, improved visibility throughout the supply chain, and automatic data updates, reducing manual errors.

- Disadvantages: Higher initial investment in RFID tags and readers compared to barcode systems, potential interference issues in certain environments, and the need for specialized infrastructure.

Comparison Table

| Method | Accuracy | Speed | Cost | Scalability |

|---|---|---|---|---|

| Manual Entry | Low | Slow | Low | Limited |

| Barcode Scanning | Medium | Medium | Medium | Medium |

| RFID | High | High | High | High |

Implementing an appropriate data collection method for manufacturing travelers is crucial for streamlining operations and improving overall efficiency. The chosen method should align with the specific needs of the manufacturing process, considering factors such as volume, complexity, and available resources.

Implementation Strategies for Manufacturing Travelers

Manufacturing travelers are a powerful tool for streamlining production and improving efficiency. Proper implementation is crucial for realizing their full potential. This involves more than just purchasing the system; it requires a well-defined strategy encompassing training, data integration, and ongoing maintenance. A successful implementation plan is key to ensuring smooth transitions and maximizing the benefits of this vital manufacturing tool.

Effective implementation of manufacturing traveler systems necessitates a phased approach. This structured methodology allows for a controlled introduction of the new system, minimizing disruptions and maximizing user adoption. Key components include meticulous planning, comprehensive training, and rigorous testing.

Steps Involved in Implementing a Manufacturing Traveler System

Careful planning is essential before initiating any traveler system implementation. This phase involves identifying the specific needs of the manufacturing process, defining the scope of the traveler system, and outlining the expected outcomes. This includes mapping out the workflow, determining the necessary data points, and selecting the right traveler type and software. Thorough preparation and clear communication throughout this crucial stage contribute significantly to a successful implementation.

- Needs Assessment and System Design: Carefully evaluate existing processes, identify areas for improvement, and determine the appropriate scope of the traveler system. Clearly define the required data fields and how the travelers will integrate with existing systems. This ensures the system meets specific manufacturing needs and improves efficiency.

- Traveler Type Selection: Choose the appropriate traveler type based on the specific needs of the manufacturing process. Consider factors like material handling, storage requirements, and the volume of information to be tracked. For instance, if a process involves complex material handling, a specialized traveler design might be essential. Conversely, a simple traveler might suffice for a more straightforward process.

- Pilot Program: Implement the system in a controlled environment. This pilot phase allows for testing the system’s functionality, identifying potential issues, and gathering feedback from users. This approach helps in fine-tuning the system before a full-scale rollout.

- Full-Scale Implementation: Roll out the system across the entire manufacturing facility. Provide comprehensive training and support to all affected employees. Continuous monitoring and adjustments are essential during this stage to address any unexpected challenges.

- Data Validation and Analysis: After full implementation, meticulously validate the data collected by the travelers. Analyze the collected data to identify areas of improvement in the manufacturing process. Regular reporting and analysis of the traveler data will provide insights into production efficiency.

Best Practices for Implementation

Adhering to best practices during implementation ensures a smooth transition and maximum benefits. These best practices involve user-centered design, data security, and regular system maintenance.

- User-Centered Design: Involve employees from all relevant departments in the design and implementation process. Gather feedback and address concerns throughout the process to foster user adoption and reduce resistance. This ensures that the system aligns with the needs and workflows of the users.

- Data Security: Establish robust security protocols to protect the sensitive data collected by the travelers. Implement measures to prevent unauthorized access and ensure data integrity. This protects confidential information and maintains the integrity of the manufacturing process.

- Regular System Maintenance: Schedule regular system maintenance and updates to ensure the system remains functional and secure. This includes addressing any bugs, implementing new features, and upgrading the software to keep pace with evolving needs.

Critical Considerations for Selecting the Right Traveler Type

Choosing the right traveler type is essential for optimal performance. Factors to consider include material handling, storage capacity, data collection capabilities, and cost. A well-selected traveler type directly impacts the efficiency and accuracy of the entire system.

- Material Handling Capabilities: Consider the weight, size, and handling requirements of the materials being tracked. Ensure the traveler type can accommodate these requirements without compromising safety or efficiency. This ensures the traveler can handle the materials involved without issues.

- Data Collection Capabilities: Evaluate the type and amount of data that needs to be collected. Select a traveler with the appropriate data collection methods, such as barcodes, QR codes, or manual input. The traveler should be able to capture the necessary data accurately.

- Cost and Maintenance: Assess the total cost of ownership, including the initial purchase price, maintenance, and potential upgrades. Choose a system that fits the budget and long-term needs. Consider factors like the cost of maintenance and potential future upgrades.

Training Employees on Using Manufacturing Travelers Effectively

Effective training is critical for successful traveler system implementation. Training programs should cover the features and functions of the system, data entry procedures, and troubleshooting steps. Proper training enables employees to use the system efficiently and reduces errors.

- Comprehensive Training Modules: Develop comprehensive training materials that cover all aspects of the traveler system. Include interactive sessions, practical exercises, and hands-on demonstrations. This ensures that all employees are adequately prepared for the system.

- On-the-Job Training: Provide on-the-job support and mentoring to employees as they begin using the travelers. Address specific questions and provide feedback to ensure correct usage. This allows for real-time assistance and immediate resolution of problems.

- Regular Training Sessions: Schedule regular training sessions to address any new features or updates to the system. This keeps employees updated on best practices and promotes consistency in data entry. Staying current on the latest features is crucial for effective usage.

Examples of Successful Implementation in Real-World Scenarios

Numerous manufacturing facilities have successfully implemented traveler systems. These implementations have resulted in significant improvements in productivity, reduced errors, and improved visibility into the manufacturing process. A notable example involves a company that reduced production downtime by 15% after implementing a new traveler system.

Analyzing Data from Manufacturing Travelers

Manufacturing travelers provide a wealth of data about production processes. Proper analysis of this data is crucial for identifying bottlenecks, inefficiencies, and opportunities for improvement. Effective analysis allows manufacturers to optimize their operations, reduce costs, and enhance overall productivity.

Analyzing the data collected by manufacturing travelers is not just about looking at numbers; it’s about understanding the underlying trends and patterns within the manufacturing environment. This involves transforming raw data into actionable insights that can guide decisions and ultimately improve the efficiency of the entire production process.

Data Visualization Techniques

Visual representations of data are vital for quickly identifying patterns and trends. Different visualization methods are appropriate for different types of data. For instance, bar charts and line graphs are effective for showing changes in metrics over time, while scatter plots can reveal correlations between variables. Histograms can illustrate the distribution of data points, and pie charts can highlight proportions of different categories.

- Bar Charts and Line Graphs: These are excellent for visualizing trends in production metrics like cycle time, defect rates, or machine downtime over time. For example, a bar chart can show the number of defects per machine type over a week, allowing quick identification of problematic machines. A line graph can track the average cycle time for a specific part across multiple production runs, highlighting areas where the process has slowed down.

- Scatter Plots: Scatter plots are beneficial when looking for correlations between variables. For example, if you suspect a correlation between machine temperature and the number of defects, a scatter plot can visualize this relationship. Points clustered in one area suggest a potential correlation, which can be further investigated.

- Histograms: These charts display the distribution of data, showing the frequency of different values. In manufacturing, histograms can be used to analyze the distribution of defect sizes or the variation in cycle times. This helps understand the process’s variability and identify potential causes of deviation.

- Pie Charts: These charts are useful for displaying proportions of different categories. For example, a pie chart can show the percentage of defects attributed to different causes (e.g., human error, machine malfunction, material defects). This visual representation allows for a quick overview of the major contributing factors.

Identifying Bottlenecks and Inefficiencies

Analyzing the data collected from manufacturing travelers can reveal bottlenecks and inefficiencies in the production process. By comparing the data against established benchmarks or expected performance levels, deviations can be highlighted, enabling the identification of specific areas needing attention.

- Comparing Data Against Benchmarks: Establish baseline performance indicators for different processes or machines. Analyze the collected data to identify any significant deviations from these benchmarks. For example, if the average cycle time for a particular operation consistently exceeds the expected time, it could indicate a bottleneck. Discrepancies can point towards process improvements needed.

- Trend Analysis: Examine data trends over time. Are certain issues recurring? Identifying patterns of slowdowns or quality issues can help pinpoint specific steps in the process that need improvement. For example, if the number of defects increases during a specific shift, it could indicate a problem with employee training or machine maintenance during that shift.

Driving Process Improvements

The analysis of manufacturing traveler data can directly drive process improvements. By identifying and addressing the root causes of issues, manufacturers can optimize their processes, reduce costs, and improve overall efficiency.

- Implementing Corrective Actions: Once bottlenecks and inefficiencies are identified, implement corrective actions to address the root causes. For example, if machine downtime is excessive, investigate and address maintenance issues, or improve preventive maintenance schedules.

- Optimizing Resource Allocation: Manufacturing travelers can reveal where resources are being wasted or underutilized. Analyzing the data can lead to optimized resource allocation, ensuring that personnel and equipment are deployed effectively and efficiently.

Case Studies of Manufacturing Traveler Success

Manufacturing travelers, those mobile data collection tools, have shown remarkable potential for improving efficiency and productivity across various manufacturing sectors. They provide a dynamic approach to capturing real-time data, enabling proactive problem-solving and informed decision-making. This section explores several case studies highlighting the positive impacts of these systems.

Automotive Manufacturing: Streamlining Production Processes

The automotive industry demands precise and consistent quality control. One case study involved a major automotive manufacturer seeking to optimize their assembly line processes. They implemented a system of mobile data collection devices, specifically designed for capturing real-time information on component placement, assembly time, and quality checks. This approach replaced paper-based logs, reducing errors and increasing data accuracy. The travelers provided detailed reports on discrepancies and potential bottlenecks, allowing for immediate corrective actions. The result was a significant decrease in production downtime and an increase in overall output, demonstrating the value of real-time feedback loops. The travelers employed in this case study included barcode scanners, digital calipers, and image capture devices for visual inspection.

Electronics Manufacturing: Enhancing Quality Control

In the electronics industry, maintaining stringent quality standards is critical. One company used travelers to monitor the quality of their printed circuit boards (PCBs). They deployed travelers equipped with high-resolution cameras and automated inspection software. The travelers captured images of the PCBs at each stage of production, allowing for instant identification of defects. This immediate feedback loop enabled the company to address quality issues early in the process, reducing rework and scrap. The results demonstrated a 15% reduction in defects and a 10% increase in production output. The travelers utilized in this case study included image capture devices with automatic defect detection software.

Food Processing: Maintaining Traceability and Safety

The food processing industry demands meticulous record-keeping to maintain traceability and safety standards. A food processing plant used travelers to track product movement through their facility. The travelers, equipped with GPS and temperature sensors, recorded the location and temperature of each product batch. This data enabled the company to track product movement and identify potential temperature excursions. The ability to identify deviations quickly allowed them to isolate affected batches and prevent potential food safety issues. The traveler system also enabled the plant to improve their regulatory compliance and customer trust. The traveler types used included GPS trackers, temperature sensors, and data loggers.

Textile Manufacturing: Optimizing Material Management

The textile industry faces challenges in managing material flow and inventory levels. One textile mill implemented manufacturing travelers to track the movement of raw materials and finished goods. The travelers enabled real-time tracking of materials from receiving to production and distribution, improving overall efficiency. This system improved inventory accuracy, minimized material waste, and reduced stockouts. The specific traveler types employed included barcode scanners and RFID tags to track inventory movements.

Thinking about a manufacturing traveler example? It’s all about efficient logistics and maximizing output. Ultimately, though, the real question for a savvy traveler is whether investing in a premium travel bag like the Thrifty Traveler is worth it. You might want to check out this post to weigh the pros and cons of is thrifty traveler premium worth it before committing.

Ultimately, a well-designed manufacturing traveler example will streamline your travel experience, making the whole process smoother and more efficient.

Thinking about a manufacturing traveler example? You might be looking to optimize your travel logistics. Using a service like Travelers Choice, you can potentially save money on your travel expenses with a coupon code. Finding a travelers choice coupon code could be just the thing to boost your budget for those manufacturing trips. Ultimately, smart travel choices can improve your bottom line in any manufacturing business.