Defining Production Traveler Templates

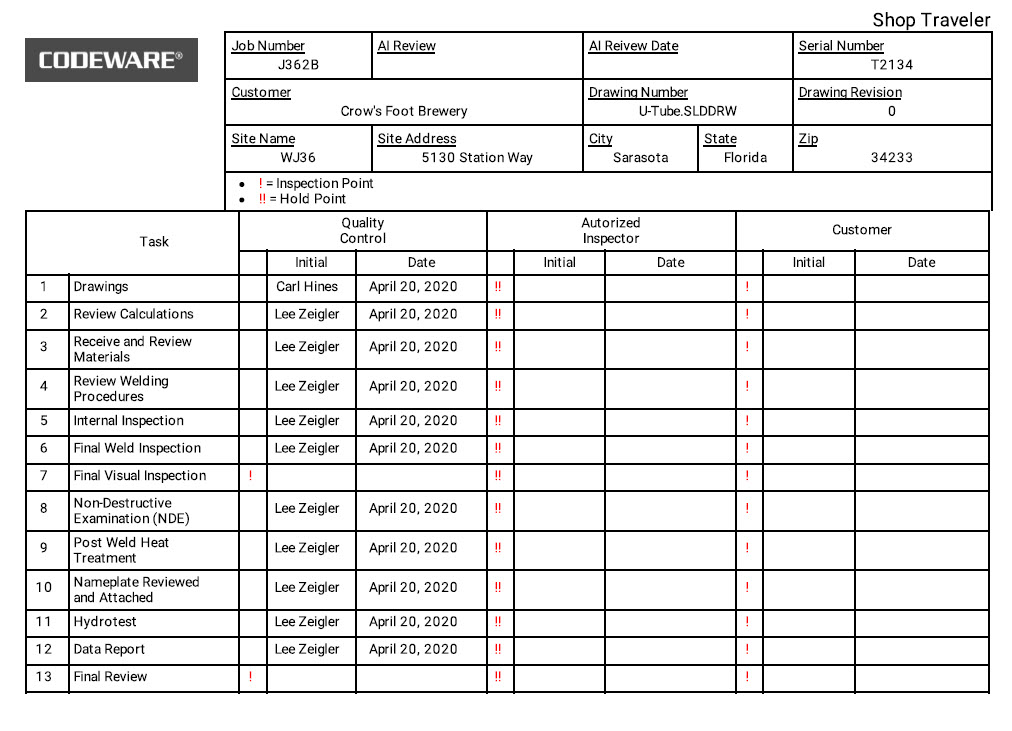

Production traveler templates are crucial documents in manufacturing and assembly processes. They act as a detailed roadmap, guiding workers through the steps required to complete a specific product or task. These templates streamline operations, reduce errors, and improve overall efficiency by providing a standardized workflow. They are vital for tracking progress, ensuring quality control, and maintaining accurate records.

This detailed explanation clarifies what a production traveler template is, its typical components, and how different types vary. It also examines the advantages of using these templates and proposes a basic template structure for a simple production process.

Components of a Production Traveler Template

A well-designed production traveler template includes several key components. These components ensure that the document is comprehensive and easy to follow. The template typically contains detailed instructions, including specific steps in the production process. This helps ensure all workers are executing the process correctly and consistently.

- Product Information: Includes the product name, part number, and any relevant specifications. This crucial information allows workers to immediately identify the item being produced and ensure they have the correct materials.

- Step-by-Step Instructions: Each step of the production process is clearly Artikeld, including detailed procedures and any specific tools or materials required. Clear and concise instructions prevent misinterpretations and ensure consistency in execution.

- Material Requirements: A list of the materials needed for each step, including quantities, types, and identification numbers. This helps prevent material shortages and ensures the right materials are used at the correct time.

- Quality Control Checkpoints: Specifies the quality checks that need to be performed at each stage of the process. This helps maintain high standards and identify potential issues early on.

- Time Estimates: Provides estimated time durations for each step or the entire process. This aids in scheduling and managing production timelines. Time estimates can be based on historical data or expert opinions.

- Worker Identification: Space to record the name of the worker completing each step. This provides traceability and accountability, critical for process improvement and quality control.

Types of Production Traveler Templates

Production traveler templates can vary depending on the specific industry and production process. The most common types are tailored to the manufacturing and assembly sectors.

- Manufacturing Traveler: Focused on the steps involved in creating a product, often involving complex machinery and processes. A manufacturing traveler might include more technical details on machine settings and operational parameters.

- Assembly Traveler: Concentrates on the assembly of components into a final product. This type of template will likely include detailed diagrams or images illustrating the assembly process, highlighting specific placement and connections between parts.

Benefits of Using Production Traveler Templates

Production traveler templates provide several key advantages for manufacturers and assembly operations. The use of these templates results in significant improvements in efficiency, quality, and cost savings.

- Improved Efficiency: Standardized processes and clear instructions lead to faster production times and reduced waste. This reduces the overall time required for each product to be manufactured.

- Enhanced Quality Control: Consistent procedures and quality checks ensure higher-quality products. This results in a lower rate of defects and fewer rework requirements.

- Reduced Errors: Detailed instructions minimize mistakes by workers, leading to higher accuracy in the production process. This directly correlates with reduced costs from errors and rework.

- Improved Communication: The standardized template facilitates clear communication among different departments and workers. This prevents confusion and promotes better collaboration.

- Increased Productivity: Streamlined processes and clear instructions empower workers, leading to increased productivity. This boosts overall output and profitability.

Basic Template Structure for a Simple Production Process

A basic template for a simple production process can be structured as follows:

| Step | Description | Materials | Time Estimate (minutes) | Quality Check | Worker Signature |

|---|---|---|---|---|---|

| 1 | Cut the material | Sheet metal, cutter | 5 | Check for straightness | |

| 2 | Bend the material | Bending machine | 10 | Check for correct angle | |

| 3 | Drill the holes | Drill bit, drill press | 15 | Check for accuracy of holes | |

| 4 | Assemble the parts | Screws, nuts | 10 | Check for proper assembly | |

| 5 | Final inspection | Quality control tools | 5 | Check for defects |

Template Structure and Organization

A well-structured production traveler template is crucial for efficient project management. It allows for easy tracking of progress, identification of potential bottlenecks, and streamlined communication between teams. A clear and consistent format ensures everyone understands the information presented, minimizing misinterpretations and facilitating smooth workflow.

Effective templates are not just about organizing data; they’re about making it actionable. A well-designed template allows for quick identification of critical information, enabling proactive problem-solving and optimized resource allocation. This leads to more predictable project timelines and reduced project costs.

Consistent Formatting and Labeling

Clear and consistent formatting enhances readability and usability. This includes using a standardized font, font size, and color scheme throughout the template. Applying consistent formatting to headings, subheadings, and data fields promotes a professional look and ensures uniformity in data presentation. Consistent labeling of fields is equally important. Using standardized abbreviations and terminology reduces ambiguity and allows for easy data entry and interpretation by all stakeholders. This prevents errors and misunderstandings.

Data Organization Methods

A well-organized production traveler template uses effective data organization methods. These methods should facilitate easy identification and retrieval of critical information. A crucial aspect is the use of logical grouping of data points. For example, grouping related tasks or activities together under a common heading makes it easier to understand the sequence and dependencies between various operations. Clear separation of different stages of production (e.g., pre-production, production, post-production) using headers or colors also enhances comprehension and helps quickly identify the current stage of a specific production task.

Examples of Effective Data Organization

Organizing data using tables is a highly effective method. Tables provide a structured format for presenting information in rows and columns, allowing for easy comparison and analysis. Using columns for different aspects of a task (e.g., task description, assigned personnel, start date, end date, status) allows for comprehensive tracking and management of production activities. Implementing a clear system for categorizing and sorting data further enhances usability. For instance, sorting tasks alphabetically or by priority level allows for quick retrieval of specific information.

Fields/Columns in a Production Traveler Template

A production traveler template should include essential fields for capturing all relevant data. A well-designed template provides a comprehensive overview of production progress, enabling efficient tracking and decision-making. A table below illustrates various fields commonly included in a production traveler:

| Field | Description | Data Type |

|---|---|---|

| Task Description | Detailed description of the task | Text |

| Assigned Personnel | Personnel responsible for the task | Text/Dropdown |

| Start Date | Date the task is scheduled to begin | Date |

| End Date | Date the task is scheduled to end | Date |

| Status | Current status of the task (e.g., planned, in progress, completed) | Dropdown |

| Progress (%) | Percentage completion of the task | Number |

| Dependencies | List of tasks that need to be completed before this one | Text/Dropdown |

| Issues/Notes | Any issues or important notes related to the task | Text |

Categorizing and Sorting Data

Categorizing data allows for quick retrieval and analysis. Using categories, such as project phase, department, or task type, helps in segmenting data. Sorting the data within categories based on various criteria (e.g., priority, due date, status) ensures efficient retrieval of specific information. Implementing a color-coding system for different statuses or priorities further enhances quick identification and comprehension. This streamlined approach allows stakeholders to focus on the most pertinent information.

Data Input and Fields

Production traveler template – A well-structured production traveler is crucial for efficient project management. Accurate and complete data input is paramount to avoid delays and ensure smooth workflow. This section delves into the critical aspects of data input, focusing on the types of data required, best practices for inputting information, and validation rules to maintain data integrity.

Planning a trip, especially to a stunning destination like the Amalfi Coast, requires meticulous planning. A well-structured production traveler template can be incredibly helpful for organizing your entire trip, from flights and accommodations to excursions. To ensure your Amalfi Coast adventure goes smoothly, consider consulting a reputable travel agent like amalfi coast travel agent. They can handle the nitty-gritty details, allowing you to focus on enjoying the breathtaking scenery.

Ultimately, a production traveler template can streamline the entire travel process, no matter where your adventures take you.

Different Types of Data

Production travelers must encompass various data types, each playing a unique role in the project. This includes, but is not limited to, project details, equipment specifications, personnel assignments, material requirements, and expected timelines.

Effective Data Input

Accurate data input is vital for the production traveler’s effectiveness. This entails meticulously entering data into designated fields, cross-checking for errors, and ensuring consistency throughout the document.

Production traveler templates are super helpful for planning, but did you know that member travel services often offer tailored solutions for travel? These services can streamline the entire process, from booking flights and hotels to managing expenses, which can be incredibly useful when paired with a production traveler template. It’s all about finding the right tools to make your production travel run smoothly.

Interactive Elements for Data Input

Using interactive elements like drop-down menus and checkboxes can enhance data input accuracy and efficiency. These elements help standardize entries, reduce human error, and ensure consistent formatting across the document.

Data Validation Rules

Robust data validation rules are essential to maintain data integrity. These rules should encompass format requirements, data ranges, and dependencies between fields to catch inconsistencies early.

Sample Data Fields

| Field Name | Data Type | Expected Format | Validation Rules |

|---|---|---|---|

| Project Name | Text | Alphanumeric, maximum 50 characters | Not blank, alphanumeric characters only |

| Equipment ID | Text | Alphanumeric, maximum 10 characters | Not blank, alphanumeric characters only, unique |

| Date | Date | YYYY-MM-DD | Valid date format, not in the future |

| Start Time | Time | HH:MM | Valid time format, not in the future |

| Quantity | Number | Integer | Positive integer, greater than zero |

| Personnel Assigned | Text | Employee ID, maximum 10 characters | Not blank, valid employee ID, existing in employee database |

| Material Type | Text | String | Dropdown menu containing valid material types |

| Status | Text | String (e.g., “Pending”, “In Progress”, “Completed”) | Dropdown menu containing valid statuses |

Template Customization and Integration

Production traveler templates, while offering a solid foundation, need tailoring to specific manufacturing processes and workflows. Customization allows for improved accuracy, efficiency, and alignment with unique company requirements. Integrating the template into existing systems streamlines data flow and reduces manual effort, creating a more automated and less error-prone process.

Integrating the template effectively is crucial for a smooth workflow. It involves adapting the template to reflect specific processes and seamlessly connecting it to existing software. Automation of data entry reduces manual errors and frees up personnel for more strategic tasks.

Tailoring the Template to Specific Needs

Production traveler templates can be customized by modifying fields, adding new ones, or restructuring existing sections. For instance, a company producing complex electronics might require detailed component tracking fields not needed in a simpler manufacturing process. This adaptation allows the template to precisely capture the specific requirements of each production run. Careful consideration of unique production processes, including materials, procedures, and quality control checks, will help tailor the template to specific needs.

Integrating the Template with Existing Systems

Integrating the template with existing software like ERP (Enterprise Resource Planning) systems or MES (Manufacturing Execution Systems) is essential for a seamless workflow. Data synchronization ensures real-time updates and avoids redundant data entry. APIs (Application Programming Interfaces) can facilitate this integration, enabling the automatic transfer of data between systems. Using a pre-built connector or custom coding can establish this connection. By leveraging existing system capabilities, the template can become a vital component of the overall production process.

Automating Data Entry and Update Processes

Automating data entry and update processes reduces human error, speeds up data collection, and ensures data accuracy. Using a spreadsheet software or dedicated software for automation, data entry can be significantly accelerated. For instance, integrating a barcode scanner allows real-time data input directly into the traveler. Automation also allows for continuous updates on the traveler, reflecting real-time status changes on the shop floor.

Best Practices for Workflow Integration

Implementing the template into the workflow should be a gradual process, starting with a pilot project to identify and resolve any potential issues. Training employees on the new template is crucial for effective use and to minimize errors. Regular audits of the template’s implementation are essential for identifying areas for improvement and ensuring ongoing effectiveness. Creating a standardized reporting mechanism to track production performance is a crucial best practice.

Flowchart of Integration Process

+-----------------+ +-----------------+ +-----------------+

| Start | --> | Template Design | --> | Data Integration |

+-----------------+ +-----------------+ +-----------------+

| |

| V

| +-----------------+

| |System Connection|

| +-----------------+

| | |

| |Data Validation |

| | |

| +-----------------+

| | Training |

| +-----------------+

| | Testing |

| +-----------------+

| | Pilot |

| +-----------------+

| |Deployment |

| +-----------------+

| | Audit |

| +-----------------+

| | Feedback & |

| | Improvement |

| +-----------------+

| |

| V

| +-----------------+

| | End |

| +-----------------+

This flowchart illustrates a phased approach to integrating the template, starting from initial design to final deployment and continuous improvement. Each step is crucial for successful implementation.

Example Templates and Use Cases

Production travelers are invaluable tools for streamlining manufacturing processes. They offer a centralized, visual representation of the production flow, enabling real-time tracking of progress and identification of potential bottlenecks. Implementing well-designed templates ensures efficiency and facilitates the timely completion of projects.

Manufacturing Process Template

This template provides a structured approach to tracking individual parts through the various stages of a manufacturing process. It’s crucial for ensuring consistent quality and timely completion.

| Part Number | Operation | Operator | Start Time | End Time | Quantity | Quality Check | Notes |

|---|---|---|---|---|---|---|---|

| 12345 | Cutting | John Smith | 09:00 | 09:15 | 100 | Passed | No issues |

| 12345 | Drilling | Jane Doe | 09:15 | 09:30 | 100 | Passed | Slight variation in hole depth, see notes |

| 12345 | Painting | David Lee | 09:30 | 09:45 | 100 | Failed | Rework required, incorrect color |

Assembly Line Template

The assembly line template is a key component for managing the flow of products through the assembly process. It ensures all components are accounted for and assembled correctly.

| Product ID | Assembly Station | Component | Quantity | Status | Operator | Start Time | End Time | Notes |

|---|---|---|---|---|---|---|---|---|

| ABC123 | Station 1 | Chassis | 1 | Completed | Alex Johnson | 10:00 | 10:15 | No issues |

| ABC123 | Station 2 | Engine | 1 | In Progress | Emily Brown | 10:15 | Waiting for parts |

Tracking Production Progress

Using these templates, production progress is monitored by systematically recording the time spent on each operation or assembly step. This allows for quick identification of delays or bottlenecks, facilitating proactive intervention and adjustments to maintain schedule.

Identifying Potential Bottlenecks or Delays

Analyzing the traveler data reveals potential bottlenecks or delays. If certain stations consistently take longer than anticipated, it signifies a potential bottleneck that requires investigation and resolution. Differences in operator performance or inadequate resources can also be identified, enabling process improvements.

Use in Various Production Environments

Production traveler templates can be adapted and used across diverse manufacturing environments, from small workshops to large-scale production facilities. Their adaptability makes them suitable for various industries, including automotive, electronics, and consumer goods.

Best Practices and Considerations

Production traveler templates are crucial for efficient and accurate project management. Proper maintenance of these templates ensures smooth workflows, reduces errors, and ultimately contributes to successful project completion. This section delves into best practices for maintaining data accuracy, handling revisions, implementing version control, ensuring data security, and effectively utilizing the template within a team environment.

Maintaining Data Accuracy and Consistency

Accurate and consistent data is paramount for reliable production traveler information. Implementing robust data entry procedures is vital. This includes clear guidelines for data input, validation rules, and regular data audits. Clear definitions for each field, along with examples, will reduce ambiguity and improve data consistency. For example, standardizing abbreviations and units of measurement will prevent discrepancies. Regular checks for errors and inconsistencies using automated tools or manual reviews, depending on the template’s complexity, are recommended.

Handling Revisions and Updates

Production traveler templates require periodic updates to reflect changing project requirements or processes. A systematic approach to handling revisions is essential. A clear revision control system, including version numbers and timestamps, will ensure that the correct version of the template is used at any given time. Documenting the reasons for each revision, such as changes in specifications or updated procedures, helps maintain a historical record of template changes and allows for easy tracking of revisions. This documentation can include a detailed change log.

Importance of Version Control

Version control is critical for maintaining the integrity and accuracy of production traveler templates. A version control system allows users to track changes, revert to previous versions if needed, and collaborate effectively on updates. This system should be integrated with the template management process to ensure that all users have access to the latest version. Utilizing a dedicated version control software, like Git, can track changes made by each team member, allowing for easy identification of errors or improvements.

Ensuring Data Security

Data security is crucial for production traveler templates, especially those containing sensitive information. Implementing appropriate access controls, restricting access to authorized personnel, and encrypting sensitive data are essential. Regular security audits, and adherence to industry best practices for data protection, will help prevent unauthorized access or data breaches. Employing strong passwords, multi-factor authentication, and secure storage solutions are crucial security measures.

Using the Template Effectively in a Team Environment

Effective team collaboration is essential for maximizing the utility of production traveler templates. Clear roles and responsibilities for each team member must be defined, ensuring everyone understands their contribution to the template. Regular team meetings to discuss the templates and any issues, alongside clear communication channels, will help maintain transparency. Establishing a central repository for the template, with appropriate permissions and access controls, will allow all authorized team members to access and update the document as needed. Utilizing a shared online platform can enhance collaboration and accessibility for the entire team.

Troubleshooting and Common Issues

Production traveler templates, while powerful tools, can sometimes present challenges. Understanding potential pitfalls and their solutions is crucial for efficient and accurate data management. This section details common problems encountered during template usage, offering practical troubleshooting steps and strategies to overcome these issues.

Data Entry Errors

Data entry errors are a frequent source of problems in production traveler templates. These errors can range from simple typos to more complex mistakes, impacting the accuracy of the data. Identifying and correcting these errors promptly is vital for maintaining data integrity.

- Typos and Incorrect Formatting: Human error is inevitable. Typos in data fields or incorrect formatting (e.g., wrong date formats, incorrect numerical values) can lead to significant problems. Carefully reviewing data fields before submission is crucial. Double-checking values against source documents, especially for critical data like part numbers and quantities, helps mitigate this risk.

- Missing or Inconsistent Data: Failing to enter all required fields can lead to incomplete records. Ensure all mandatory fields are populated correctly. Inconsistencies in data formats (e.g., inconsistent units of measure) require immediate attention to avoid downstream issues. Implement data validation rules within the template to flag these issues automatically.

- Incorrect Data Type: Entering the wrong data type (e.g., entering a text value where a number is expected) is another common error. Template design should incorporate data validation rules that ensure the correct data type is entered for each field. For instance, a field for “quantity” should only accept numerical input. These validation rules prevent the upload of invalid data.

Inconsistencies in the Data

Inconsistencies in the data can stem from various sources, such as different data entry methods, or discrepancies between different systems. Addressing these inconsistencies promptly prevents errors and ensures data accuracy.

- Duplicate Records: Duplicate entries for the same production traveler can lead to confusion and errors in reporting. Implement checks to identify and prevent duplicates within the template, for instance by utilizing unique identifiers for each traveler.

- Inconsistent Units of Measurement: Using different units of measurement (e.g., kilograms and pounds) for the same data field can cause confusion. Templates should enforce consistent units to avoid errors. For example, if the template is for parts in a manufacturing facility, use consistent units for quantities (e.g., always use pieces or kilograms).

- Differences in Data Format: Inconsistencies in data formats can occur if different sources use different formats for the same data. For example, dates can be formatted in various ways (MM/DD/YYYY, DD/MM/YYYY, YYYY-MM-DD). Ensure consistency throughout the template and use standardized formats to avoid misinterpretations.

Missing or Incomplete Data

Missing or incomplete data is a common challenge, especially in the initial stages of data collection. Strategies to handle these issues are crucial to maintaining data integrity.

- Identifying Missing Data: The template should clearly highlight missing or incomplete fields. This can be achieved through visual cues, such as a color change or an asterisk next to the required fields.

- Addressing Missing Data: If a field is missing data, the template should allow for a ‘not applicable’ or ‘unknown’ option, or provide a mechanism for the user to specify when the data will be available.

- Data Collection Strategies: Establish clear procedures for obtaining missing data. This could involve prompting users to collect the information, providing additional forms for missing data, or integrating the template with other data sources.